| 手机微信: 17821719638 | 电话: 021-37785053 | 邮箱: zepengtech@163.com | 中文 英文 |

| 专业销售美国品牌康气通Controlairlnc膜片式气缸和膜片产品、有单缸和双缸类型款式 |  |

|---|

| 首 页 | | | 新闻动态 | | | 公司介绍 | | | 产品中心 | | | 项目案例 | | | 联系我们 | | | 营业执照 |

|---|

|

||

美国康气通ControlAir最著名的气动专家,Controlair膜片式气缸全系列: 滚动膜片式气缸s4L|s6L|s9L|s12L|康气通s16L|s36Lus4Lus6Lus9Lus12LControlAir us16LControlAir隔膜气缸气缸膜片膜片S-6-L 膜片式气缸: |

||

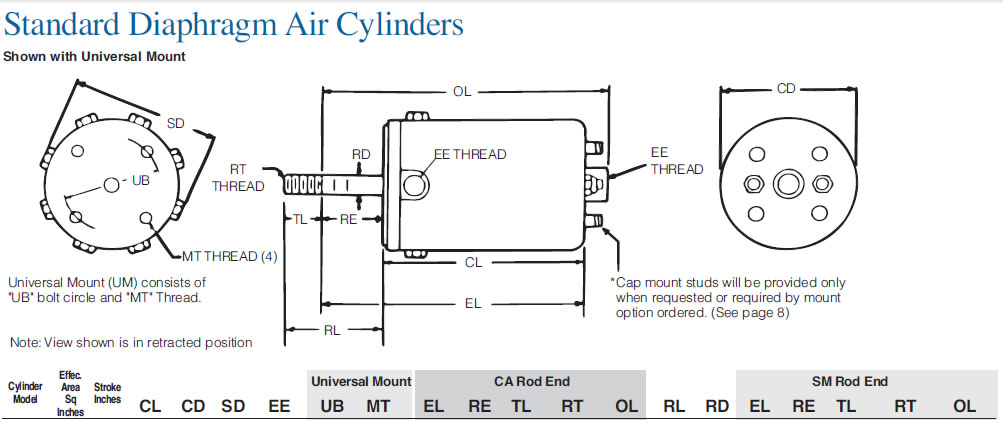

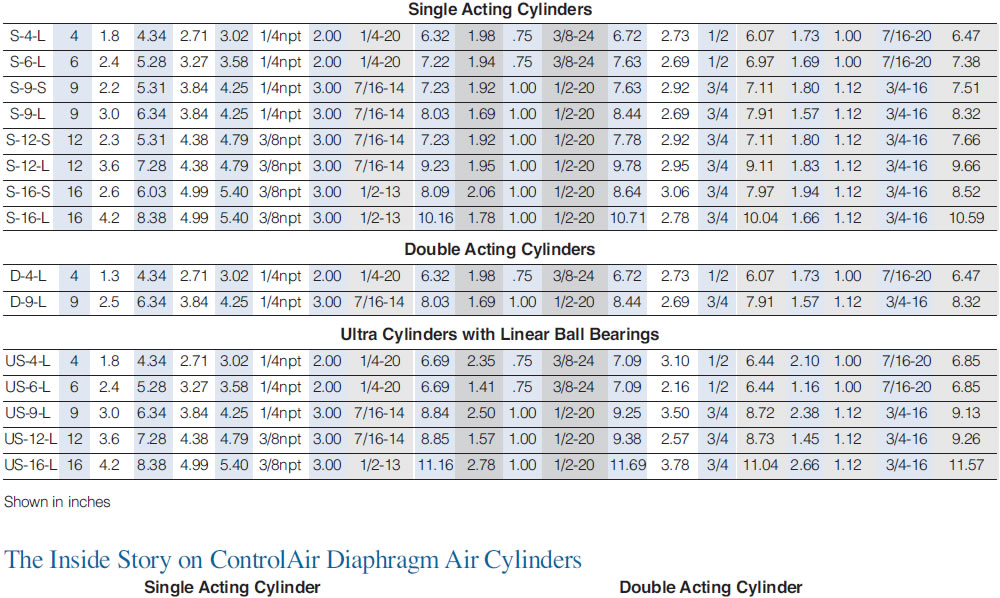

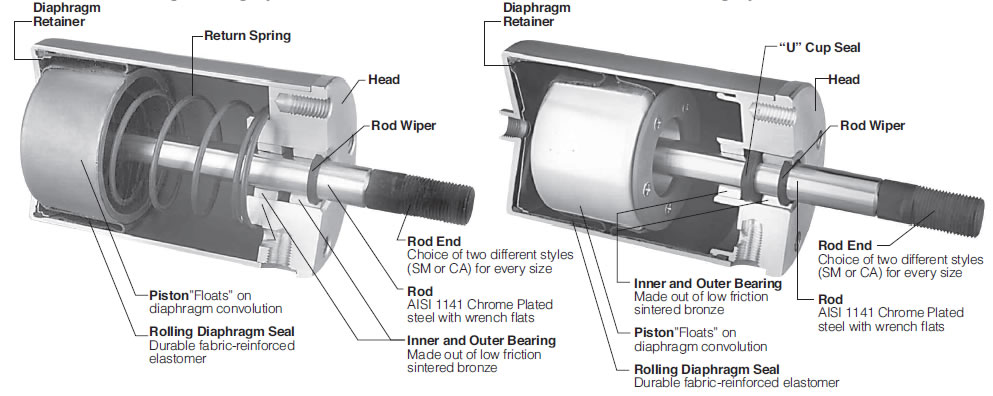

气缸规格、旋转气缸型号、无杆气缸型号、气缸型号和规格尺寸图、双向气缸型号、大全气缸型号的含义、亚德客气缸型号、大全薄型气缸型号、大全旋转气缸型号、大全标准气缸型号规格表Rolling Diaphragm Air Cylinders The friction free alternative,The "Rolling Diaphragm" Air Cylinder The advent of the long stroke rolling diaphragm as a means of low-friction dynamic sealing has led to the development of the ControlAir Diaphragm Air Cylinder.These cylinders provide virtually frictionless conversion of pneumatic pressure to linear force,and offer such operating features as: •Super Sensitivity •Absolutely No Lubrication Required •Low Hysteresis •No Blow-By Leakage •Wide Temperature Variations The rolling diaphragm creates the perfect seal for friction free cylinders.It is a durable, flexible membrane shaped like a top hat with the peak of the hat fastened to the end of the piston and the "brim" clamped to the cylinder cap. Inside of the cylinder this forms a long-lasting frictionless seal between the piston head and cylinder wall. The fabric reinforced elastomer rolling diaphragms are produced utilizing a microprocessor controlled process that is recognized as the leading edge mode of production. Custom diaphragm material design allows for operation of the cylinders at temperatures from -75°F to 400°F.Ultra Cylinders-Linear Ball Bearings For applications where the absolute minimum in friction free performance is required, ControlAir has developed the Ultra Cylinder. These cylinders combine the advantages of the rolling diaphragm seal with Grade "A" linear ball bearings and a hardened steel rod to produce virtually zero friction operation. For the ultimate in precise response to small pressure variations, choose "The Ultra." Modifications Our standard Diaphragm Air Cylinders are easily modified to meet individual customer requirements. Modifications can include, but are not limited to, diaphragm, bearing, or rod materials, rod configurations, and spring design. Applications The performance advantages of our Diaphragm Air Cylinders make them ideal for applications such as Web Tensioners, Dancer Roll Tensioners, Roll Loaders, Valve Actuators, Accumulators, Positioners, and Impact Absorbers to name a few. |

|

|

| Controlair膜片式气缸资料说明: | 气缸资料选型一 | 气缸资料选型二 |

|---|

| 膜片式气缸: ControlAir调压器、 ControlAir调压阀、 ControlAir减压器、 ControlAir减压阀、 ControlAir精密调压阀、 ControlAir精密减压器、 ControlAir精密减压阀、 ControlAir压力调节器、 ControlAir压力调节阀、 ControlAir电动减压器、 ControlAir电动减压阀、 ControlAir过滤减压器、 ControlAir过滤减压阀、 ControlAir电流压力转换器、 ControlAir电气转换器、 ControlAir继动器、 ControlAir继动阀、 ControlAir气缸 |

|---|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||